Knowledge: Tanning

Tanning:The process of changing from hides to leather

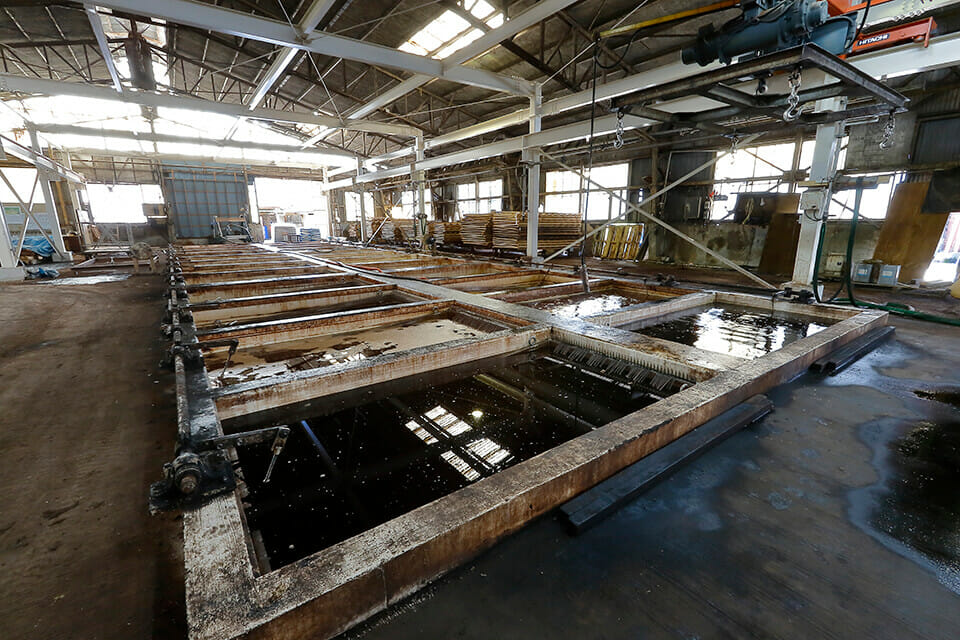

Hides become leather through a process called tanning. A tanning agent is bound to the collagen fibers of the skin to make it a supple leather material. Most of the raw leather of leather products is imported from overseas, but there are many tanners in Japan that perform tanning. Currently, there are two main tanning methods: vegetable tanning, which is a plant-derived ingredient, and chrome tanning, which is basic sulfuric acid. The quality of leather changes greatly depending on the composition of the chemicals used for the tanning agent.

The overall tanning process is basically the same for all tanners, but there are some differences that lead to originality.

For example, Sanyo, who we talked to, splits the back of the leather after the tanning process is completed. Mr. Shioda says, "This is more efficient because it has a larger floor surface."

In recent years, there have been an increasing number of cases where creators and designers go directly to tanner to place orders, and tanners plan and create their own products. Each has their own recipe, and tanning that brings leather to life with the technique that has been accumulated so far. It's worth knowing their outstanding technique.

Chrome tanning

Tanning using basic chromium sulfate as a tanning agent. Compared to tannins, it can be tanned in a short period of time. Has good color development, excellent elasticity and water resistance. In addition, it is soft and easy to process. Most of the leather used for clothing is chrome-tanned.

Vegetable tanning

A method of tanning using the astringency of plants, which has been practiced since ancient times. In some cases, it may take several weeks to complete the entire process. The finish is robust and is often used for men's bags. It absorbs dyes well, but the colored leather of the tannin itself is also aesthetically beautiful.