Creative: Himeji Leather

Himeji Leather:The guardian deity of white tanning (Himeji Tanning) that continues to protect the ancient manufacturing method that has been handed down in Japan

From “Japanese Leather 1st Edition” Published 2008

Until recently, the "white tanning" that was handed down in Himeji was on the verge of extinction. In terms of sumo wrestling, the wrestler was forced onto the ‘tokudawara’ (the edge of the ring) . Himeji is the birthplace of white tanning in Japan, and its history dates back to the end of the Heian period or even older. The most distinctive feature of this tanning method is that the river bacteria, salt, and rapeseed oil are all that are used to complete the tanning without using any chemicals. While chemical tanning completes the entire process in about one month, white tanning takes two to four months. Due to the time and work involved, many white tanning workshops in Himeji changed to tanning with chemicals. By the way, the "white" in white tanning, refers to the color of the tanned leather. White-tanned leather is finished in a light milky white color. This color is the hallmark of "white tanning" and is the reason why chrome tannin tanning did not completely eliminate the technique. Of course, that's not all. We can still see white-tanned leather products because of the presence of craftsmen who stubbornly adhered to this centuries old technique in Himeji. Masahiko Morimoto is one of those craftsmen who has inherited the techniques that have been handed down from ancient times. We asked what the driving force was behind his decision to protect this technique. "I think it’s because my father was very skilled at it. I don’t think I can move onto a different method until I become better than him. My determination and sincerity about the craft are what keeps me going.”

Mr. Morimoto is a man of few words, exactly what you would expect from a craftsman. At the time of the interview, I could not actually see him work since he was between tanning. "When the red spider lilies bloom, the water temperature of the river is so high that I can’t let the leather touch it. Once I start the tanning process, I can’t rest. I have to keep my eye on the river while exposing the raw skin to the water. It's important to fix the leather so that it flows but doesn't drift down the river. You need to make it flutter in the water about 20 to 25 times a minute."

A spatula hanging stand that has been with Mr. Morimoto for more than half a century. The base is a pine and oak pillar, and the tip is a tool that is indispensable for white tanning with a knife-shaped metal fitting.

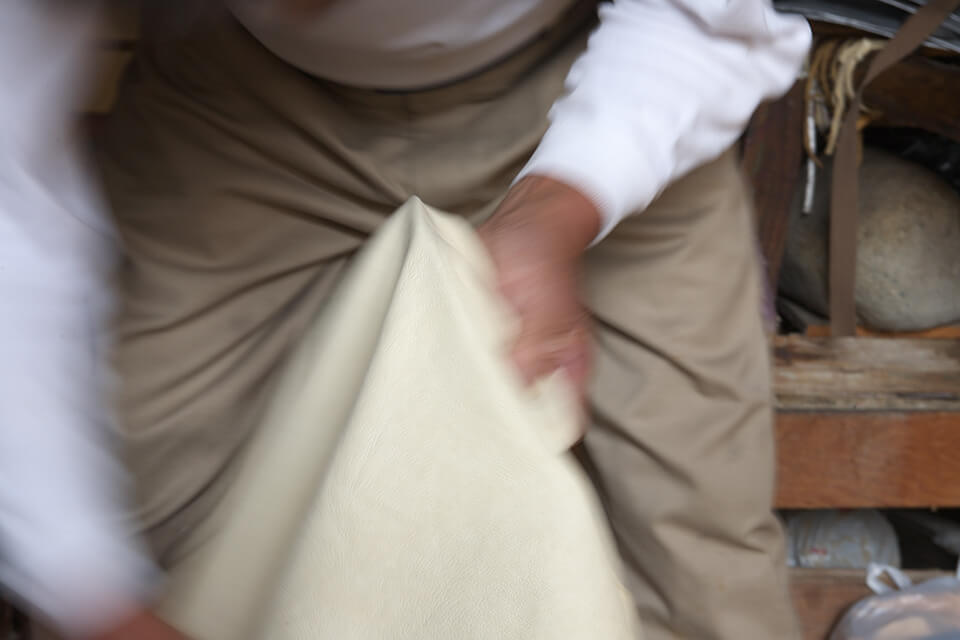

The Ichikawa river flows in front of the workshop, and the part of the stream is where Morimoto exposes his leather. However, working with nature isn’t always easy. Morimoto says it's particularly tough this year. The water temperature is too high. It is said that once soaked in the river, there is no turning back, so he needs to "discuss with the river" to determine when to soak. "If there is a sudden shower in the distance, the river stones will make noise before the river rises. This also brings in sand and mud, which will enter the pores and damage the leather. To prevent it, I need to turn the leather over, which is harder than it seems." We asked Mr. Morimoto to show us some of the process. Mr. Morimoto begins work with the almost finished white-tanned leather in his hand. It is a process of putting leather with the grain side up on a spatula rack with a metal piece like a knife attached to the tip of an oak tree and stretching it. It's called staking. Once he starts working, Mr. Morimoto’s gentle expression becomes that of a keen craftsman. Watching him powerfully and swiftly stretching the sheet of leather, you wouldn’t think that he is almost 70 years old. He hangs a piece of leather with a spatula on a log, puts his weight on his knees and stretches it with all his strength. Every process is hard work. However, the finished leather is worth the heavy labor. It is just unbelievably soft and beautiful. Even though it is not painted, the entire leather shines in a light greenish white color.

"The good thing about this leather is that it doesn't get damaged in the sun. Rather, it gets whiter and whiter. This tanning makes sense to the user. The more you use it, the whiter it becomes. There is no other tanning like this," says Mr. Morimoto, proudly.

Left) Leather shavings that appear during staking. The work is like sharpening the leather.

Right) A stretching log that has been used for over 50 years. The surface is smooth because the leather is wrapped around it and polished.

As already mentioned, white-tanning craftsmen are extremely rare , and Mr. Morimoto's successor problem has always been a concern. But the situation is changing. It means that a successor to Mr. Morimoto may appear. According to Mr. Morimoto, who speaks in a few words, his son-in-law has come to help and may become a successor. In that case, the history of Himeji white tanning, which has continued for more than a thousand years, may be inherited without interruption.

White tanning has been used for harnesses, armor, and drums because of its unique color and toughness. More recently, it has been reaffirmed for its practicality and attractiveness as a leather material, as well as its historical value. Mr. Morimoto's white tanning is also used for bags under the name "Himeji Tan".

At one point, white tanning was on the verge of being "pushed off" from the stage. Now, with the influence of environmentally conscious production processes, it seems that it’s making a comeback.

Place the leather on the stakingstand, prepare the grain side, and stretch the leather. By repeating the same process, the texture and suppleness of leather and beautiful "white" color are achieved. The amount of time and work put into it is unbelievable.