Creative: Soka

Soka:The pride and unity of the leather craftsmen who gave birth to the Soka brand

The gentle autumn sunshine illuminates the Ayase River, and the lush pine trees are reflected on the surface of the water. An unusual object is added to the atmospheric scene of Soka; The world's first Canadian canoe made of cowhide. 4 adult cows worth of cowhide was used. The canoe was completed twenty-three years ago by leather craftsmen in Soka City, Saitama Prefecture. They struggled to sew the leather together with a special sewing machine and apply water-repellent treatment to the tanned leather. The extra work was worth it, and it was popular with the citizens at events in the city, and was highly evaluated at an Italian leather exhibition. However, the biggest significance of the canoe is that it was the first step in creating the "Soka brand".

Soka brand-. Many readers may think of senbei or rice crackers when they hear the name Soka. However, leather is actually a famous local industry in Soka along with senbei and yukata. Before the war, the tanning factory in Tokyo’s Mikawashima began to relocate one after another in anticipation of the abundant water resources of Soka and its closeness to Tokyo, and the town soon became lively with the smell of leather and the appearance of craftsmen. In the mid 50s, Soka was the 4th largest leather production city in Japan. Finishing and sewing factories also relocated, and now nearly 200 leather-related companies exist in and around the city. However, the Soka leather was never fully recognized, and at one point, a TV crew that came to cover Soka's specialty products completely ignored the Soka leather industry. Mr. Isao Suzuki, who has been manufacturing and selling reptile leather products in the city for nearly 50 years, felt a sense of crisis that ‘Soka's leather industry will become extinct’. "I called on young leather craftsmen to come together to create something that could promote the leather industry in Soka City, and we decided on a cowhide canoe. For a total of three weeks, more than a dozen leather craftsmen gathered at night after work to make the canoe. It may have been a strange sight, but when the craftsmen who normally work separately gathered for a common purpose, a sense of unity was born. And we began to discuss the future of the leather industry in Soka."

Currently, Mr. Suzuki, a technical adviser for the LEATHER TOWN SOKA Project team, helps promote Soka’s leather industry and its skilled techniques backed by years of experience. Back then, he told his fellow craftsmen about his thoughts on Soka’s leather industry during a night of drinking. It turned out that everyone shared an awareness of the problem. The days of creating the future of Soka leather began. "The biggest strength of the leather industry in Soka City is that we can do everything from procuring raw leather to commercializing all here in the city. We handle a wide variety of leather such as cows, pigs, sheep goats, and reptiles, and there are shoes, bags, and accessory processors. Every necessary manufacturer is gathered here. We have to take advantage of this."

Nitto leather, one of the leathers made in Soka, is widely used in traditions and festivals such as taiko drums, Noh theater, Kabuki, sumo, and temples and shrines.

Environmentally conscious manufacturing is inevitable, and Soka is no exception. Eco-leather is the focus of many vendors. Eco-leather is leather and leather products made in an environmentally conscious process. Efforts have begun in the world since the mid-1990s, and eco-leather is an important trend when considering the future of leather and the sustainability of the leather industry. Also, for the past few years, Soka has been working on biodegradable leather. "Rice bran oil" extracted from rice bran is used for tanning the leather. It has been partially put into practical use, for its good texture and its physical properties that are resistant to bending and tension.

"Fortunately, many leather companies were voluntarily working on being more conscious of the environment, so we were able to produce it rather quickly. Sure, the leather industry in Soka is smaller than other areas. However, I think that by working together, we were able establish our own unique style and present it to the market."

Even so, it is amazing that manufacturers in processes can work together on one thing. "Originally, Soka's leather craftsmen were lone wolves," laughs, says Munetake Miyamoto, CEO of Nitto Leather, who was the first to start leather manufacturing in Soka City. "But when we think about the next generation, we need to come together. Once Soka leather becomes more well known, it will be easier for the next generation of craftsmen to carry the torch."

You can feel the responsibility as a pioneer of Soka leather and his concern for the younger generation in his words. The shortage of successors is a problem that plagues all industries, but at least in the Soka leather industry, the nurturing of younger generations seems to be going well. Even in Nitto leather, where they carefully tan leather for taiko drums by hand, young craftsmen are working energetically. And it's not just eco-leather that they will take over.

Crocodile business items, their most popular products. System notebook 180,000 yen, leather-wrapped oil-based pen 36,540 yen, pen case (for one) 48,000 yen (all reference prices, exhibited in Paris in commemoration of the 150th anniversary of friendship between Japan and France)

Hiroshi Iwaihara, CEO of Daito Roman, whose main business is tanning cowskin and pigskin, said, "The driving force of Soka's leather industry is the ‘bond’ we have with each other. Because we have a good relationship, we can collaborate across barriers. We’re able to have fun because we aren’t forced." Kazunori Kawai, president of Kawai Sangyo, which manufactures gelatin raw materials from leather, also cites "the strong bond between people without thinking of business or profit" as the strength of Soka's leather industry. The relationship between Soka leather craftsmen is truly amazing. While each of them takes pride as a skilled craftsman, they continue to have respect for one another. They all push forward to one goal while having fun, they’re like kids having fun in a park. The Soka brand, including eco-leather, was meant to be born from the bonds between craftsmen formed in this area.

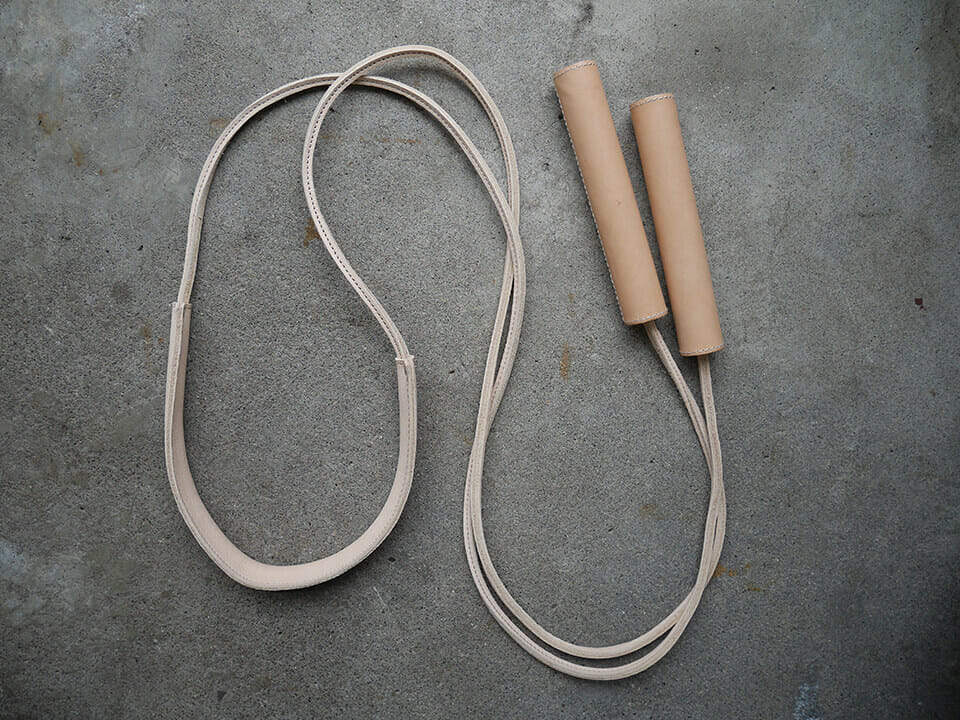

The characteristic of Soka leather is that a wide range of leathers such as soft leather (left) and cowhide (right) are handled within the same tanning process. Every single effort by the craftsmen supports the quality of the product.

Soka City is not only trying to promote their leather, but also the city itself. Soka once prospered as the second post station on the Nikko Kaido. Such cultural figures such as Watanabe Kazan, Ino Tadataka, and Masaoka Shiki visited this area and left records in their texts and works. In order to make the most of this vibrant history, the city of Soka is currently attracting attention for their urban renewal plan called "Imayou / Soka-juku".

"Soka Juku has always been hospitable to travelers and sent them on their way. It means that they were able to communicate and connect with people in other regions. The leather industry in Soka also needs to make products that convey their ideas and hopes nationwide. We have to express the creator's message not only from an eco standpoint, but also functionality and design. "

Looking ahead, President Tatsuo Ito of Ito Sangyo talks about his strategy. Ito Sangyo is a tanning company that handles a lot of soft leather such as sheepskin and goatskin. They have introduced state-of-the-art tanning equipment and are focusing on eco-leather production. Skilled techniques passed down from generations, craftsmanship, and future vision. In Soka's leather industry, all the pieces needed for the new era of leather are coming into place.

In the middle of a long journey, it was Matsuo Basho who wrote, "I finally arrived at an inn at Soka." Now, Soka Leather has arrived at the "sign called Eco Leather". The journey continues. The craftsmen who created the Soka brand move forward, confident and without hesitation.

(From top left)

Tatsuo Ito: CEO of Ito Sangyo Co., Ltd. Ito Sangyo manufactures soft leather used for gloves. He serves as the chairman of the Leather Craftsmen's Association and works to promote Soka leather.

Munetake Miyamoto: CEO of Nitto Leather Co., Ltd. Nitto Leather was the first company to start manufacturing leather in Soka City. He is very passionate about the local leather industry and is still active.

Hiroshi Iwaihara: CEO of Daito Roman Co., Ltd. Cowhide tanned at Daito Roman is used for shoes and handbags. He has been working on eco-leather for 15 years.

Kazunori Kawai: CEO of Kawai Sangyo Co., Ltd. Kawai Sangyo makes gelatin raw materials from pig skins gathered from the north of Shizuoka. He is also active as a young leader in the leather industry in Soka.